Dispersion

In the field of dispersion, the focus is on:

- Dispersion on a laboratory and pilot plant scale

- Energy-efficient production of dispersions

- Process optimization and improvement of dispersion quality

- Process-accompanying characterization (inline, online, atline)

Some selected examples of our activities in the field of dispersion processes are:

- Selection and testing of suitable processes depending on product properties

- Conducting test days to compare different dispersion processes

- Production of suspensions and emulsions in small series and customer samples

- Supporting upscaling to industrial scale

Laboratory

Precision in processing and analysis thanks to state-of-the-art technology

The competences of the EZD are complemented by a close exchange of experience with the application laboratories of equipment manufacturers. This ensures that the equipment in our laboratories is always state-of-the-art.

Technical equipment – laboratory scale

Dissolver

Task

- Mixing unit for pre-dispersion, intensive and time-saving mixing, and further dispersion

Implementation

- Various mixing tools (toothed pulleys, double suction pulleys)

Parameters

- Speed: 600–8000 min-1 (peripheral speed depends on geometry)

- Typical batch size from 1 - 10 l

Typical applications

- Paints, lacquers and surface systems

- Resin systems and adhesives

Three-roll mill

Task

- Homogenising, deaerating, wetting and fine grinding of suspensions

- A defined upper particle size limit can be achieved by precisely adjusting the gap distances between the rollers

Implementation

- Defined constraint system through set gap distance

Parameter

- Gap widths between 5 - 121 µm

- Speeds between 30 - 600 min-1

- Throughput up to 18 l/h, processing possible from just a few milliliters

- Cooling and heating possible in the range of 10 °C – 60 °C

Typical applications

- Paints and lacquers

- Resin systems and adhesives

- Coatings

- Highly filled ceramic slurries

- Pigment pastes and masterbatches

Dual asymmetric centrifuge

Task

- High-speed mixing unit for intensive, time-saving, and reproducible mixing, degassing, homogenizing, and dispersing, even of very small quantities

- Screening of formulations

Implementation

- Combination of centrifugal forces acting in different planes by double rotation of the mixing bowl

Parameters

- Speed: 300 - 3,500 min-1

- Typical batch size from 5 - 1,000 g

- Mixed programs can be used

Typical applications

- Paints and lacquers

- Resin systems and adhesives

- Recipe development

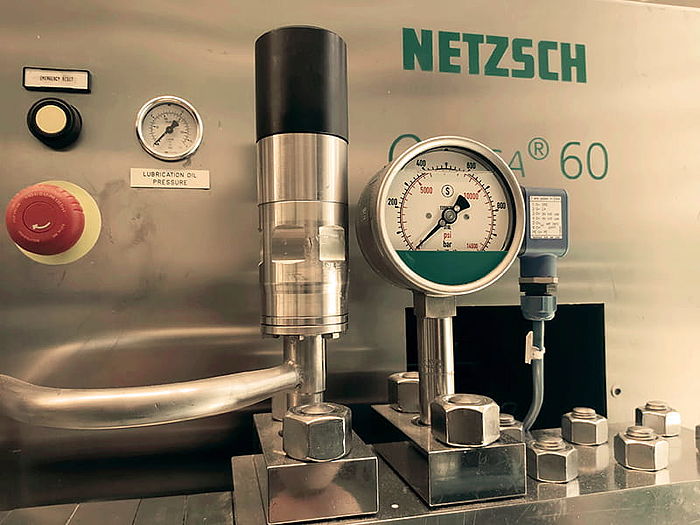

High-pressure homogenizer

Task

- Dispersion of agglomerated particles

- Production of emulsions

Conversion

- In the dispersing unit, energy is converted into very high velocities by pressure differences

- Force effect on the product due to turbulence, cavitation and specifically applied shear forces

Parameters

- Maximum working pressure: 2,000 bar

- Processing at 11 l/h at 2000 bar (with 22 l/h at 1000 bar)

Typical areas of application

- Coatings and surface systems

- Resin systems

- Food and beverages

Intensive mixer

Task

- Mixing, drying, granulating, agglomerating, plasticising, kneading, compounding, degassing, tempering, dispersing, suspending, coating

Conversion

- Mixer with functional separation of the material movement and the mixing function

- Rotating mixing vessel ensures circulation of the material to be mixed, intensification possible through inclined position

- different mixing tools

- Batch process

Parameters

- max. mixing volume: 1 l

- Vacuum: 50 - 1,100 mbar

- Speeds:

- Mixer: 300 - 5,000 min-1

- Container: 12 - 65 min-1

- Inclination: 0 - 30°

Typical applications

- Paints and lacquers

- Battery suspensions (Li-Ion)

- Resin systems and adhesives

- Coatings

- Granulation and agglomeration of fine powders

- Production of polymer masterbatches

Wet grinder centrifuge

Task

- Preliminary tests to develop test parameters for the agitator ball mill and recipe adjustments

Implementation

- Variable program creation for reproducible tests

- Coolable test room

Parameter

- Rotational speed: max. 1,500 min-1 (corresponding circumferential speed of the agitator ball mill max. 13.2 m/s)

- Use of grinding media-filled cuvettes (2 ml, 15 ml, 50 ml)

- The maximum number of cuvettes per run is 2x 20 2 ml, 6x 15 ml, 6x 50 ml

- Grinding media:

- Design: Ceramic, steel, and glass

- Ø 0.1 – 2.4 mm

Typical applications

- Paints and coatings

- Pharmaceuticals and cosmetics

- Paper coatings

- Ceramic suspensions

- Food

- Nano suspensions

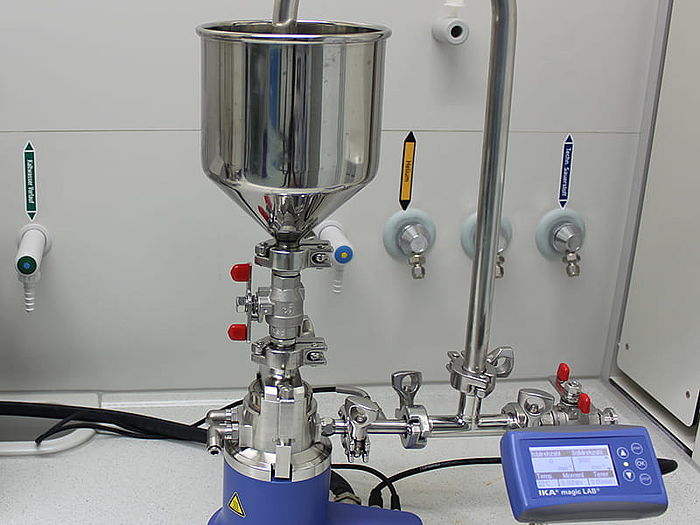

Rotor-stator disperser

Task

- Multifunctional laboratory machine for mixing, wet grinding, dispersing and adding powders to liquids

Implementation

- Single-stage dispersing module Ultra-Turrax (rotor-stator)

- Multi-stage high-performance dispersing machine Dispax-Reactor (rotor-stator for fine particle size reduction with narrow particle size distribution)

- CMS module for solid-liquid mixing

- Colloid Mill for wet or fine grinding of hard and granular raw materials or for the production of very fine emulsions

- Ultra-Turrax as batch disperser possible

Parameters

- Speed: 3,000 and 26,000 min-1 (depending on the module used)

- Typical batch size from 20 - 2,000 ml

- Can be used for inline, batch or recirculation operation

Typical applications

- Resin systems

- Cosmetics and medicine

- Paints and pigments

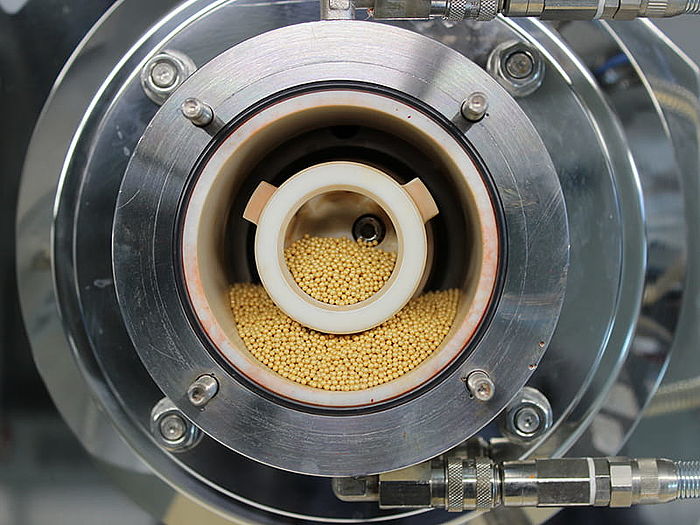

Agitator ball mill

Task

- From dispersion to genuine comminution of suspensions

- Scale-up to comparable production machines possible

- Preliminary tests possible using wet grinding centrifuge

Implementation

- Process possible as batch or in a cycle

- Agitator shaft in the grinding chamber ensures movement of the grinding media

- Product stress due to shear, pressure and impact effect of the grinding media

Parameters

- Speed: 1,000 - 4,500 min-1 (peripheral speeds 3.5 - 18 m/s)

- Typical batch size from 0.15 - 15 l

- Shaft and grinding chamber design: Stainless steel, ceramic and PU

- Grinding chamber volume: 240 - 910 ml

- Grinding media:

- Design: Ceramic, steel and glass

- Ø 0.1 - 2.4 mm

Typical applications

- Paints and lacquers

- Pharmaceuticals and cosmetics

- Paper coatings

- Ceramic suspensions

- Food

- Nano suspensions

Tumbling mixer

Task

- Mixing / homogenising powders, granulates and solid/liquid materials

Implementation

- Diagonal arrangement of the mixing vessel ensures a tumbling motion and thus a uniform, three-dimensional material rearrangement

- Different vessels can be used in the mixing vessel

Parameters

- Speed: 5 - 40 min-1

- Batch size: max. 5 kg

Typical areas of application

- Production of homogeneous powder mixtures

Ultrasonic homogenizer

Task

- Dispersing, deagglomerating, wetting and real comminution of solids in suspensions by means of ultrasound

Conversion

- Batch processing starting at just a few milliliters

- Circulating mode with water-cooled flow cell

- Stress caused by cavitation, impact, turbulence, and shearing

Parameters

- Selection of several ultrasonic devices that can be used depending on the application

- Highest energy input with max. power input: 1,000 W and maximum process pressure of 5 bar possible

Typical applications

- Paints and lacquers

- Resin systems and adhesives

- Coatings

Ultra-centrifugal mill

Task

- Dry fine comminution of soft to medium-hard and fibrous materials

- Material-friendly and analysis-oriented sample preparation in the shortest possible time

Implementation

- Comminution principle: impact, shear

- Use of different rotors and screens

- Optional cryogenic grinding using liquid nitrogen

- Increased throughput possible using cyclone separator

Parameter

- Feed volume: up to 300 ml

- Feed size: < 10 mm

- Final fineness: < 40 µm

- Speed: 6,000 - 18,000 min-1

Typical applications

- Sample preparation of dry solids for analyses

- Size reduction of fibrous solids

- Dry grinding of minerals and ores

Universal mixer

Task

- Mixing and kneading of medium to high viscosity material systems

- Incorporation of high solids content into silicone masses

- Carrying out various process steps in a mixing unit: wetting, plasticising, homogenising, deagglomerating, heating, cooling, degassing

Conversion

- Incorporation and mixing with two counter-rotating Sigma blades

Parameters

- Speed: 10 - 100 min-1

- Batch size: 500 cm³

- Vacuum possible

- Cooling and heating possible in the range of 10 °C – 200 °C

Typical applications

- Highly filled, pasty masses

- Incorporation of solids into rubber, plastics, silicone, adhesives

Technical equipment – technical scale

Agitator ball mill

Task

- From dispersion to real grinding of suspensions

- Scale-up to comparable production machines possible

- Preliminary tests possible using wet grinding centrifuge and LabStar

Implementation

- Process can be carried out in batches or in a continuous cycle

- Agitator shaft in the grinding chamber ensures movement of the grinding media

- Product stress due to shearing, pressure, and impact of the grinding media

Parameters

- Speed: 650 – 2,700 rpm (peripheral speeds 3.4 – 14 m/s)

- Typical batch size of 15 – 40 l

- Shaft and grinding chamber design: stainless steel and ceramic

- Grinding chamber volume: 1.6 – 4 l

- Grinding media:

- Design: Ceramic, steel, and glass

- Ø 0.1–2.4 mm

Typical applications

- Paints and varnishes

- Pharmaceuticals and cosmetics

- Paper coatings

- Ceramic suspensions

- Food

- Nano suspensions

Dissolver

Task

- Mixing unit for pre-dispersion, intensive and time-saving mixing, and further dispersion

Implementation

- Various mixing tools (toothed pulleys, double suction pulleys, HPD pulleys)

Parameters

- Speed: 300–5000 rpm (peripheral speed depends on geometry)

- Typical batch size of 15–40 l

- Optional vacuum

Typical applications

- Paints, varnishes, and surface systems

- Resin systems and adhesives

Inline disperser

Task

- Suction, wetting, emulsifying, and dispersing

- Effective pre-dispersing of powder intake under process vacuum

- Scale-up for production plants possible

Implementation

- Various tools optimized for powder intake or dispersion according to the rotor-stator principle

- Guide jet mixer for support in the feed hopper

Parameters

- Speed: 600 – 8,100 min-1

- Typical batch size of 7 – 15 l, 18 l – 75 l

Typical applications

- Paints, varnishes, and surface systems

Medium pressure homogeniser

Task

- Dispersion of agglomerated particles

- Production of emulsions

Functional principle

- In the dispersing unit, energy is converted into very high velocities (up to 300 m/s) by pressure differences.

- Force effect on the product through turbulence, cavitation and specifically applied shear and impact forces

Parameters

- Working pressure between 10 and 700 bar

- Delivery rate 18 - 60 l/h

- Typical batch size 5 - 100 l

Typical applications

- Paints and coatings

- Resin systems

- Food and beverages

SKZ · German Plastics Center

Friedrich-Bergius-Ring 22

97076 Würzburg

Telefon: +49 931 4104-0

E-Mail: info@skz.de

Route berechnen

97076 Würzburg

Telefon: +49 931 4104-0

E-Mail: info@skz.de

Route berechnen

SKZ Training Center – Welding

Frankfurter Str. 19 c

97082 Würzburg

Telefon: +49 931 4104-123

E-Mail: training@skz.de

Route berechnen

97082 Würzburg

Telefon: +49 931 4104-123

E-Mail: training@skz.de

Route berechnen

SKZ · Branch office Halle

Training and Research Center

Köthener Str. 33a

06118 Halle (Saale)

Telefon: +49 345 53045-0

E-Mail: halle@skz.de

Route berechnen

Köthener Str. 33a

06118 Halle (Saale)

Telefon: +49 345 53045-0

E-Mail: halle@skz.de

Route berechnen

SKZ · Branch office Horb

Training Center

Rauher Grund 9

72160 Horb am Neckar

Telefon: +49 7451 62457-0

E-Mail: horb@skz.de

Route berechnen

Rauher Grund 9

72160 Horb am Neckar

Telefon: +49 7451 62457-0

E-Mail: horb@skz.de

Route berechnen

SKZ · Branch office Peine

Training Center

Woltorfer Str. 77, Halle G

31224 Peine

Telefon: +49 5171 48935

E-Mail: peine@skz.de

Route berechnen

Woltorfer Str. 77, Halle G

31224 Peine

Telefon: +49 5171 48935

E-Mail: peine@skz.de

Route berechnen

EZD · Branch office Selb

European Center for Dispersion Technologies (EZD)

Weißenbacher Str. 86

95100 Selb

Telefon: +49 9287 99880-0

E-Mail: ezd@skz.de

Route berechnen

Weißenbacher Str. 86

95100 Selb

Telefon: +49 9287 99880-0

E-Mail: ezd@skz.de

Route berechnen

Sales partner – Italy

PROCHEMA S.r.l.

Via Buonarotti 175

20900 Monza, Italy

Telefon: +39 039 281561

E-Mail: info@prochema.it

Route berechnen

Via Buonarotti 175

20900 Monza, Italy

Telefon: +39 039 281561

E-Mail: info@prochema.it

Route berechnen

Sales partner – Romania

Plastics Bavaria Equipment & Systems srl

Str. Iancu Jianu, nr. 26

500178 Braşov, Romania

Telefon: +40 268 412 559

E-Mail: office@plastics-bavaria.ro

Route berechnen

Str. Iancu Jianu, nr. 26

500178 Braşov, Romania

Telefon: +40 268 412 559

E-Mail: office@plastics-bavaria.ro

Route berechnen

Training Center Middle East

SKZ · Training Center Middle East

Muntazah Complex (Exit - 25)

Jebel Ali Village - Dubai (VAE)

Telefon: +971 4 8845001

E-Mail: info@skz-me.com

Route berechnen

Muntazah Complex (Exit - 25)

Jebel Ali Village - Dubai (VAE)

Telefon: +971 4 8845001

E-Mail: info@skz-me.com

Route berechnen

Sales partner – Poland

Dopak Sp. z o. o

Ul. Kwiatkowskiego 5a

52-407 Breslau, Poland

Telefon: +48 71 35 84 000

E-Mail: dopak@dopak.pl

Route berechnen

Ul. Kwiatkowskiego 5a

52-407 Breslau, Poland

Telefon: +48 71 35 84 000

E-Mail: dopak@dopak.pl

Route berechnen

Sales partner – Turkey

Polmak Plastik

Ikitelli OSB Demirciler Sanayi Sitesi, E2 Blok No:420

34490 Başakşehir İstanbul | Turkey

Telefon: +902126718170

E-Mail: info@polmakplastik.com

Route berechnen

Ikitelli OSB Demirciler Sanayi Sitesi, E2 Blok No:420

34490 Başakşehir İstanbul | Turkey

Telefon: +902126718170

E-Mail: info@polmakplastik.com

Route berechnen

Sales partner – Austria

EZD · Location Selb

European Centre for Dispersion Technologies (EZD)

c/o SKZ – KFE gGmbH

Weißenbacher Str. 86

95100 Selb

Phone: +49 9287 99880-0

eMail: ezd@skz.de