Coating

The Coating department focuses on three key areas:

- Powder coating

- Wet painting

- Inkjet and screen printing

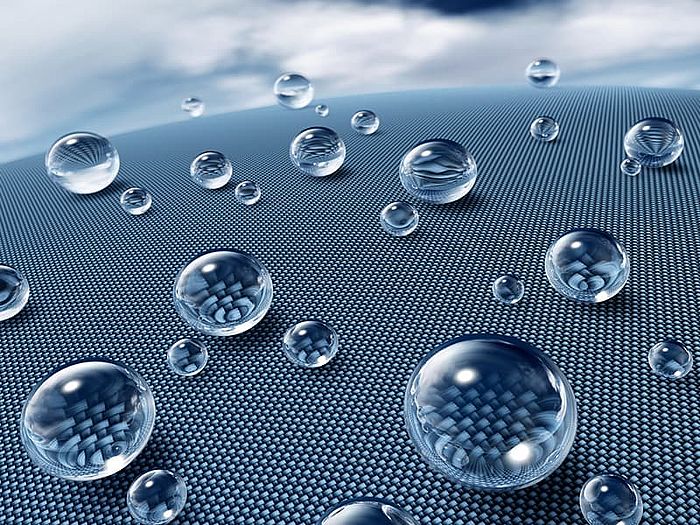

Here, both coating systems and inks are developed and tested for their applicability and layer and surface properties. Particular attention is paid to functional coatings (e.g., electrically conductive, superhydrophobic, scratch-resistant) and innovative inkjet applications.

Paint and ink properties to be examined:

- Viscosity and surface tension

- Particle size and stability

- Compatibility with different substrates

Coating properties to be investigated:

- Adhesion strength

- Coating thickness

- Defects (holes, orange peel)

Surface properties

- Surface tension (contact angle)

- Electrical conductivity

- Roughness

- Haptics

- Scratch resistance

- Wash and scrub resistance

Precision in processing and analysis thanks to state-of-the-art technology

The competences of the EZD are complemented by a close exchange of experience with the application laboratories of equipment manufacturers. This ensures that the equipment in our laboratories is always state-of-the-art.

Technical equipment

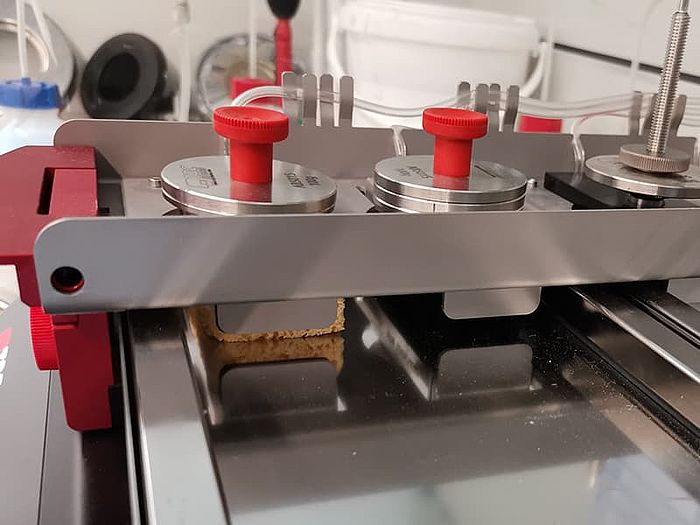

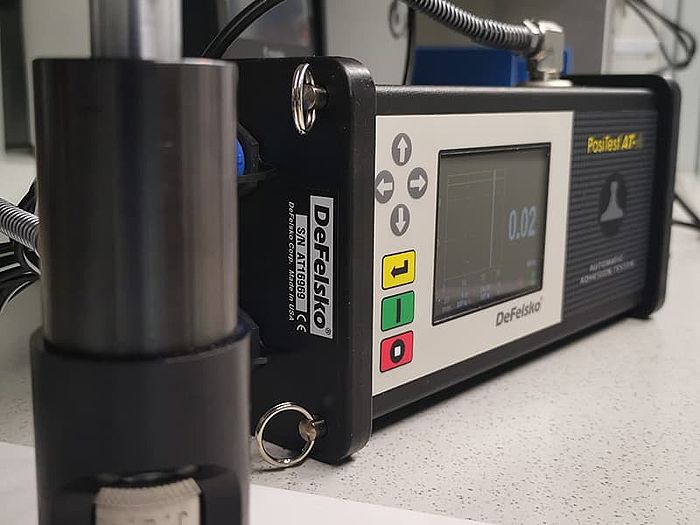

Adhesion

- The adhesion testers automatically perform tear-off tests to assess the adhesion/cohesion of coatings to metal, wood, concrete and similar substrates.

- Test stamp size 20 mm and 50 mm

- Standards DIN EN ISO 16276-1, DIN EN ISO 4624, ASTM D4541

Coating thickness measurement

- Ultrasonic coating thickness gauge for different substrates (metal, plastic, glass etc.)

- Measuring range 13 - 1,000 μm - Minimum layer thickness of a single layer: 13 μm

Tensiometer

- Measurement of the interfacial and surface tension of liquids using the plate method

- Measurement of contact angles on rectangular, round and cylindrical samples

- Contact angle measurement on powders using the Washburn method

- Determination of liquid density

- Determination of penetration and sedimentation of dispersions

- Measurement of surfactant properties; CMC determination; dosing via micro-dispenser

- Temperature range: 20 °C - 100 °C

- Measuring range: 1 - 2,000 mN/m

Digital microscope

- Magnification 20x - 2500x

- Head can be swiveled 90

- 3D images

- Roughness measurement

Abrasion resistance

- Automatic washability and abrasion tester including 2 pumps for test liquid supply

- Lifting/pushing speed: 1-60 strokes/min.

- Stroke/push length: 20-300 mm

- Max. specimen width: 70 mm per channel (with 4 tools)

- Max. specimen length: 350 mm

- Test according to ISO 11998, ASTM D 4213, ASTM D 2486

Taber abrasion tester

- Testing according to EN 13329, NEMA LD 3-2000, EN 438-2, ISO 4586-2 NALFA LF-01, ASTM D 3884, ASTM D 3389

Contact angle measuring system

- Portable instrument for measuring the contact angle (water, diiodomethane)

- Calculation of surface free energy according to Owens-Wendt-Rabel-Kaelble, Wu, Zisman and Fowkes

Conductivity meter

- 4-point measuring method for measuring conductors and semiconductors in the lower resistance range.

- Measuring range: 10-4 - 107 Ω x cm.

- It is used for measurement in the low resistance range:

- of the specific surface resistance

- the volume resistivity (Ω·cm)

- the specific electrical conductivity (S/cm)

Lattice cutter

- ISO 2409 & ASTM D3359

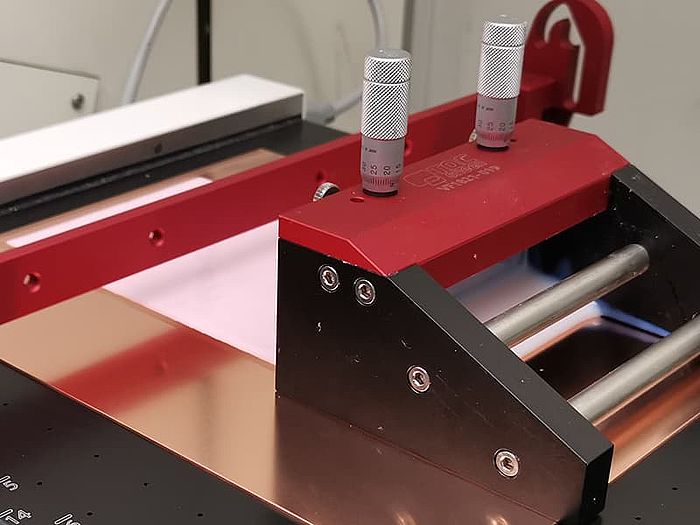

- Automatic film applicator for the production of uniform coatings on a wide variety of substrates (metal, plastic, glass, etc.)

- Max. Size of test area: A3 (297 x 420 mm)

- Hardness test rod ISO 1518

- Drying time recorder: ISO 9117-4

- Hand gun with corona charging for coating different substrates

- Production of environmentally friendly, functional powder coatings

- Substrates: metal, plastic and glass after pre-treatment

Automatic paint booth

- Highest reproducibility

- Painting with very small amounts of paint (> 5 ml) possible

- Substrate size 300 x 200 mm

- Spraying process programmable

Manual paint booth

- Spray gun: SATAjet X 5500 HVLP paint spray gun O-nozzle 1.3

Printing systems for inks (digital printing) (DT)

- Temperature control up to 80 °C

- Print heads: RicoGen5; Seiko 1536 M-RC

- Dropwatcher

- UV lamp 395 nm, 16 W

- Print&Go

High-frequency rheometer

- Frequency range: 1 Hz to 10,000 Hz

- Temperature range: 5 °C to 80 °C

- Viscosity range: From 1 mPa⋅s

- Required sample quantity: <0.1 ml

- TriPAV High-frequency rheology: Frequency sweep from 1 Hz to 10,000 Hz, duration < 5 minutes

Online rheometer

- Online rheological evaluation of the grinding progress during dispersion

- Viscosity range:

- 100 – ~50,000 mPa·s@ 10 s-1

- 10 – ~5,000 mPa·s@ 100 s-1

- 1 – ~500 mPa·s@ 1000 s-1

- Temperature range: 20 °C - 40 °C

- Continuous measurement data acquisition

Stability analyzer

- On- and at-line measuring system for analyzing the stability of suspensions

- Temperature range: RT-60 °C

- Concentration range: Up to 95% vol

Rotational viscometer

- At-line viscosity evaluation during dispersion

- Viscosity range of 40,000,000 mPa·s

Liquid color measurement

- On-line color measurement for evaluating color strength and dispersion progress

- Resolution of 3.5 nm between 400 and 700 nm

97076 Würzburg

Telefon: +49 931 4104-0

E-Mail: info@skz.de

Route berechnen

97082 Würzburg

Telefon: +49 931 4104-123

E-Mail: training@skz.de

Route berechnen

Köthener Str. 33a

06118 Halle (Saale)

Telefon: +49 345 53045-0

E-Mail: halle@skz.de

Route berechnen

Rauher Grund 9

72160 Horb am Neckar

Telefon: +49 7451 62457-0

E-Mail: horb@skz.de

Route berechnen

Woltorfer Str. 77, Halle G

31224 Peine

Telefon: +49 5171 48935

E-Mail: peine@skz.de

Route berechnen

Weißenbacher Str. 86

95100 Selb

Telefon: +49 9287 99880-0

E-Mail: ezd@skz.de

Route berechnen

Via Buonarotti 175

20900 Monza, Italy

Telefon: +39 039 281561

E-Mail: info@prochema.it

Route berechnen

Str. Iancu Jianu, nr. 26

500178 Braşov, Romania

Telefon: +40 268 412 559

E-Mail: office@plastics-bavaria.ro

Route berechnen

Muntazah Complex (Exit - 25)

Jebel Ali Village - Dubai (VAE)

Telefon: +971 4 8845001

E-Mail: info@skz-me.com

Route berechnen

Ul. Kwiatkowskiego 5a

52-407 Breslau, Poland

Telefon: +48 71 35 84 000

E-Mail: dopak@dopak.pl

Route berechnen

Ikitelli OSB Demirciler Sanayi Sitesi, E2 Blok No:420

34490 Başakşehir İstanbul | Turkey

Telefon: +902126718170

E-Mail: info@polmakplastik.com

Route berechnen

European Centre for Dispersion Technologies (EZD)

c/o SKZ – KFE gGmbH

Weißenbacher Str. 86

95100 Selb

Phone: +49 9287 99880-0

eMail: ezd@skz.de